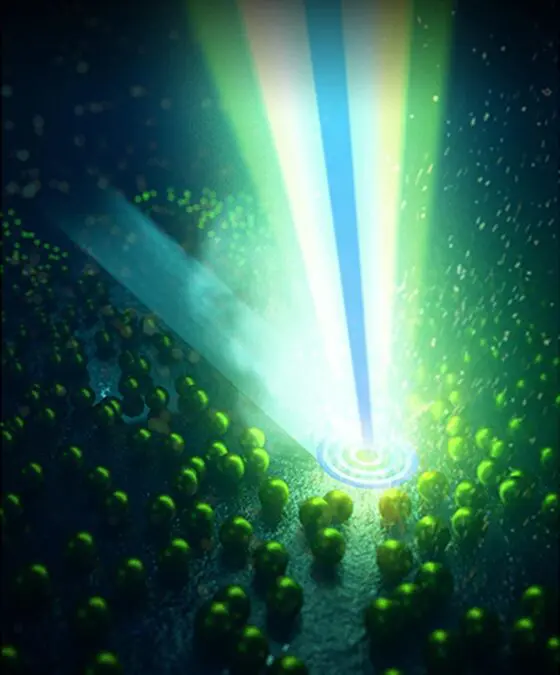

To address porosity and defects in metal 3D printing, Lawrence Livermore National Laboratory researchers experimented with exotic optical laser beam shapes known as Bessel beams — reminiscent of bullseye patterns. They discovered the beams had unique properties such as self-healing and non-diffraction and reduced the likelihood of pore formation and “keyholing,” a porosity-inducing phenomenon exacerbated by the use of Gaussian beams. Credit: Veronica Chen/LLNL

While laser-based 3D printing techniques have revolutionized the production of metal parts by greatly expanding design complexity, the laser beams traditionally used in metal printing have drawbacks that can lead to defects and poor mechanical performance.

Researchers at Lawrence Livermore National Laboratory (LLNL) are addressing the issue by exploring alternative shapes to the Gaussian beams commonly used in high-power laser printing processes such as laser powder bed fusion (LPBF).

In a paper published by Science Advances, researchers experimented with exotic optical beam shapes known as Bessel beams — reminiscent of bullseye patterns — which possess a number of unique properties such as self-healing and non-diffraction. They discovered that the application of these types of beams reduced the likelihood of pore formation and “keyholing,” a porosity-inducing phenomenon in LPBF exacerbated by the use of Gaussian beams. The work is featured on the journal’s September 17, 2021, cover.

LLNL researchers said the work indicates that alternative shapes such as Bessel beams could alleviate the chief concerns in the LBPF technique: the large thermal gradient and complex melt pool instabilities occurring where the laser meets the metal powder. The issues are predominantly caused by Gaussian beam shapes that most off-the-shelf, high-power laser systems typically output.

“Using Gaussian beams is a lot like using a flamethrower to cook your food; you don’t have a lot of control over how heat is deposited around the material,” said lead author and LLNL research scientist Thej Tumkur Umanath. “With a Bessel beam, the fact that we redistribute some of that energy away from the center means we can engineer thermal profiles and reduce thermal gradients to aid microstructural grain refinement and, ultimately, result in denser parts and smoother surfaces.”

Tumkur, who also won a first place award at LLNL’s 2019 Postdoc Research Slam! competition for the work, said Bessel beams significantly expand the laser scan parameter space over traditional Gaussian beam shapes. The result is ideal melt pools that are not too shallow and don’t suffer from keyholing — a phenomenon in which the laser creates a strong vapor and causes a deep cavity in the metal substrate during builds, as LLNL researchers have previously found. Keyholing creates bubbles in the melt pool that form pores and leads to degraded mechanical performance in finished parts.

One other drawback of conventional beams is that they are prone to diffraction (spreading) as they propagate. Bessel beams afford a greater depth of focus due to their non-diffractive properties. Consequently, the authors observed an increased tolerance to the placement of the workpiece with respect to the laser’s focal point using Bessel beams. Placement is a challenge for industrial systems that often rely on expensive and sensitive techniques for positioning an in-progress build within the focused beam’s depth of focus each time a layer of metal powder is deposited.

“Bessel beams have been used extensively in imaging, microscopy and other optical applications for their non-diffractive and self-healing properties, but beam-shape engineering approaches are rather uncommon in laser-based manufacturing applications,” Tumkur explained. “Our work addresses the seeming disconnect between optical physics and materials engineering in the metal additive manufacturing community by incorporating designer beam shapes to achieve control over melt pool dynamics.”

The LLNL team shaped the beams by running the laser through two conical lenses to produce a donut shape, before passing it through additional optics and a scanner to create “rings” around the central beam. Installed in a commercial printing machine in LLNL’s Advanced Manufacturing Laboratory, the researchers used the experimental setup to print cubes and other shapes from stainless steel powder.

Through high-speed imaging, researchers studied the dynamics of the melt pool, observing a substantial reduction in melt pool turbulence and mitigation of “spatter”— the molten particles of metal that fly from the laser’s path during a build — which generally leads to pore formation.

In mechanical studies and simulations, the team found that parts built with Bessel beams were denser, stronger and had more robust tensile properties than structures built with conventional Gaussian beams.

“Industry has long sought the ability to increase control of the LPBF process to minimize defects,” said Ibo Matthews, principal investigator on the project prior to becoming LLNL’s Materials Science Division leader. “Introducing complex structure to the laser beam adds increased flexibility to precisely control the laser-material interaction, heat deposition and ultimately the quality of the prints.”

LLNL computer scientist Saad Khairallah used the LLNL-developed multiphysics code ALE3D to simulate the interaction of both Gaussian and Bessel beam laser shapes with single tracks of metal powder material. By comparing the resulting tracks, the team found the Bessel beam demonstrated improved thermal gradients over Gaussian beams, encouraging better microstructure formation. They also achieved better energy distribution with Bessel beams, avoiding the “hot spot” generation found in Gaussian beams, which produce deep melt pools and form pores.

“Simulations allow you to get detailed diagnostics of the physics taking place and therefore allow you to understand the fundamental mechanisms behind our experimental findings,” Khairallah said.

Just one of many pathways for improving the quality of 3D-printed metal parts being studied at LLNL, beam shaping is a cheaper option than alternative scanning strategies because it can be done at little cost by incorporating simple optical elements and can reduce the expense and time involved in post-processing techniques typically needed for parts built with Gaussian beams, Tumkur said.

“There’s a big need to produce parts that are robust and defect-free, with the ability to print very large structures in a cost-effective fashion,” Tumkur said. “To make 3D printing truly compatible with industrial standards and move beyond conventional manufacturing approaches, we need to address some fundamental issues that occur at very short temporal regimes and microstructural scales. I think beam shaping is really the way to go because it can be applied to print a wide range of metals ubiquitously and be incorporated into commercial printing systems without posing significant integrability challenges as other alternate techniques tend to do.”

Researchers at LLNL are currently experimenting with other beam shape engineering strategies as part of an ongoing partnership with GE Global Research and are planning to investigate complex laser beam and polarization-shaping approaches for greater control over the quality of printed parts.

Reference: “Nondiffractive beam shaping for enhanced optothermal control in metal additive manufacturing” by Thejaswi U. Tumkur, Thomas Voisin, Rongpei Shi, Philip J. Depond, Tien T. Roehling, Sheldon Wu, Michael F. Crumb, John D. Roehling, Gabe Guss, Saad A. Khairallah and Manyalibo J. Matthews, 15 September 2021, Science Advances.

DOI: 10.1126/sciadv.abg9358

Co-authors on the paper include LLNL scientists and engineers Thomas Voisin, Rongpei Shi, Phil Depond, Tien Roehling, Sheldon Wu, Michael Crumb, John Roehling and Gabe Guss. The Laboratory Directed Research and Development program funded the work.